WHAT COMPONENTS MAKE UP A TIRE?

The bead core of the tire determines its diameter and ensures a secure seat on the rim. Generally the bead core of a tire consists of a wire bundle. In folding tires, the wire is replaced with a hoop of aramid fibers.

The carcass is the “framework” of the tire. The textile material is rubber coated on both sides and cut at a 45 degree angle. With this angle placed in the rolling direction, the carcass provides the tire’s necessary stability. All Schwalbe carcasses are made of polyamide (nylon). Depending on the quality requirements of the tire, the carcass materials are woven in various densities.

The rubber compound of a tire consists of several components:

Natural and synthetic rubber

- Fillers, e.g. carbon black, chalk, silica

- Softeners, e.g. oils and lubricants

- Anti-aging agents (aromatic amines)

- Vulcanizing aids, e.g. sulphur

- Vulcanization accelerators; e.g. zinc oxide

- Pigments and dyes

Depending on the compound, the rubber content is around 40-60%. The filler amounts to 15-30% and the remaining components approx. 20-35%.

Almost all Schwalbe tires have a puncture protection belt, with the exception of special lightweight and sports tires, where this feature is purposely excluded. Even our standard tires are equipped with an effective puncture protection belt made of natural rubber and reinforced with Kevlar® fibers (K-Guard). In the case of the Marathon tires the 3 mm thick GreenGuard ensures the renowned high puncture protection.

Furthermore, our top of the range tires have highly efficient puncture protection systems, which are specifically adapted to particular requirements, for example RaceGuard, V-Guard or SmartGuard.

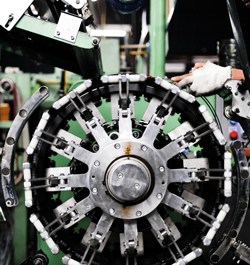

HOW IS A BICYCLE TIRE MANUFACTURED?

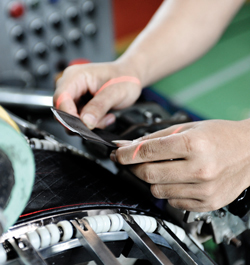

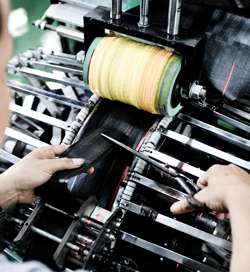

The carcass is applied to the building drum, cut and then sliced. As a next step, the wire or aramid bundles are inserted and the carcass is folded from both sides. The 45 degree-angle carcass material is now layered and forms a tire with a diagonal structure.

In this phase, the respective puncture protection layer is inserted. Finally, the tread is applied exactly in the center of the tire.

But the green tire is still in a pliable form without a tread. Only during the vulcanization process in the mold, does the tire get its tread and its elastic properties.

The green tire is pressed into a tire mold by a special heating tube and – like in a waffle iron - vulcanized at approx. 170 degrees for five to six minutes.

Only after vulcanization can it be called rubber. Now the tire has its elastic properties and its tread. After the production process every tire undergoes a strict quality control. Every tire is meticulously inspected once again. Continuous checking of random samples ensures correct weight and run-out.

Anker

WHERE ARE SCHWALBE TIRES MANUFACTURED?

All Schwalbe tires and butyl tubes are manufactured in our factory in Vietnam. The production is a joint venture between Ralf Bohle GmbH and the Korean family-owned company Hung-A.

The fact that Schwalbe tires are manufactured in South East Asia is rooted in the company's history. Bohle used to be a very small trading company that dealt in bicycle parts of all kinds. The Schwalbe story begins in 1973 when our company founder Ralf Bohle imported bicycle tires from Korea to Germany for the first time. He found this business so interesting it became his sole focus from that point on. Then as now, the business is run in close partnership with Hung-A - so all Schwalbe tires have been produced in Asia since the start of Ralf Bohle GmbH.

WHAT IS THE REASON FOR SCHWALBE MANUFACTURING THEIR TIRES IN ASIA?

As described above, this is partly due to the history of the company. Schwalbe tires have never been manufactured in Germany. They have always been manufactured in Asia in collaboration with our Korean partner company Hung-A. The most important raw material for tire production – natural rubber – also comes from the Southeast Asian region. If the tires were produced in Europe, most of the primary materials would have had to be imported. Another reason is that a large part of the bicycle industry has its bicycles produced in Asian countries. The delivery distances for our products from the factory to assembly on new bicycles are therefore comparatively short.

WHAT ARE THE WORKING CONDITIONS IN THE SCHWALBE PRODUCTION FACILITIES?

There are three working shifts. A shift lasts eight hours, and the working week in Indonesia and Vietnam is usually six days. The wage level is well above the national average in both countries. We have a strong interest in retaining our employees in Vietnam in the long term by providing a good working environment. For example, the production of a bicycle tire consists to a large extent of manual work. The experience and personal skills of our colleagues on the assembly machines therefore have a very significant influence on the quality of the finished tire. And reliably maintaining consistently high quality is one of the essential characteristics of Schwalbe tires!

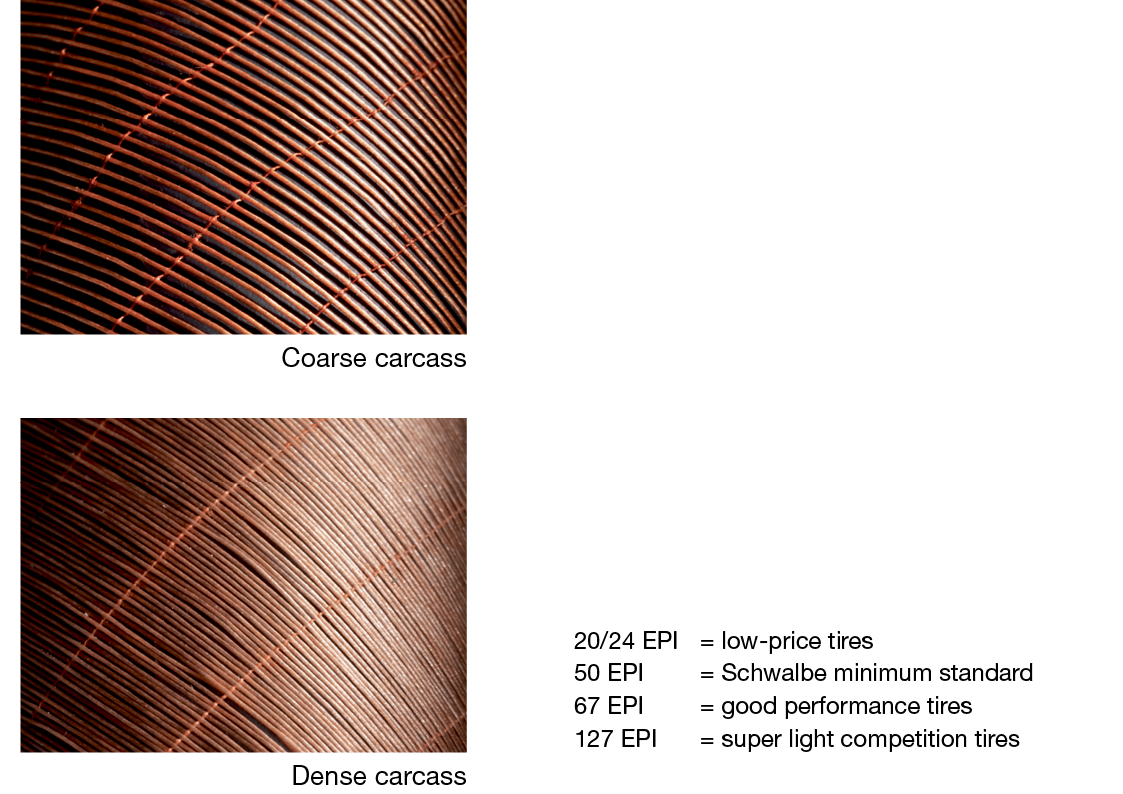

WHAT DOES EPI MEAN IN RELATION TO THE CARCASS?

In principle, the more close-meshed a carcass is woven, the higher the quality of the tire. A dense carcass is important for low rolling resistance and good riding properties. At the same time, puncture protection increases, because carcasses with a high strand density are difficult to puncture.

However, this does not apply to the extremely fine 127 EPI carcasses, as each strand is sheer and quite vulnerable. The best compromise for low weight and resistance is around 67 EPI.

In most of our top tires we use a 67 EPI carcass. Weight and rolling resistance can be reduced even further by using a 127 EPI carcass. But at the same time, these tires are more vulnerable to damage. Therefore, we intentionally use the 127 EPI carcasses only for light competition tires, where weight is an important factor.

Most bicycle tires worldwide are certainly manufactured with coarse 20 or 24 EPI materials. This material has no longer been used at all by Schwalbe for a couple of years now. Even very low-priced Schwalbe tires already have a state-of-the-art 50 EPI carcass.

But be cautious when comparing EPI indications, as often the number of strands of all carcass layers are added together. An indication of 200 TPI results e.g. from 3 layers of 67 EPI each underneath the tread.

With all EPI numbers above 150, it should be assumed that the figures have been calculated by adding up the strands in all layers. Schwalbe only indicates the material density in one carcass layer.

Commonly, there are 3 carcass layers underneath the tread.

DOES A PERFECT RUBBER COMPOUND EXIST?

We prepare universal compounds which comprise all relevant properties as far as possible, as well as special compounds with extreme characteristics. The universal compounds are used, for example, for the ENDURANCE rubber compound in the case of the Marathon tire or the SPEEDGRIP compound in the case of the sport tires. A very effective possibility to optimize all relevant properties in one tire is the Triple Compound Technology.

Special rubber compounds are used in various areas of the tread – substructure, bead seat, center – which exploit their respective strengths.

WHY ARE REFLECTIVE LINES USED?

The European mark of conformity certifies conformity with all legal requirements for lighting equipment (ECE – Regulations 88). That means for the reflective lines, light refection is sufficiently strong and bright, even at an unfavorable angle.

Because of this considerable safety advantage, we began to use reflective lines years ago as standard for all high-quality touring and city tires.