SCHWALBE PUBLISHES DETAILED LIFE CYCLE ASSESSMENT FOR GREEN MARATHON

SAVINGS OF 41% CO2EQ COMPARED TO PREDECESSOR MODEL THANKS TO RECYCLED AND RENEWABLE MATERIALS

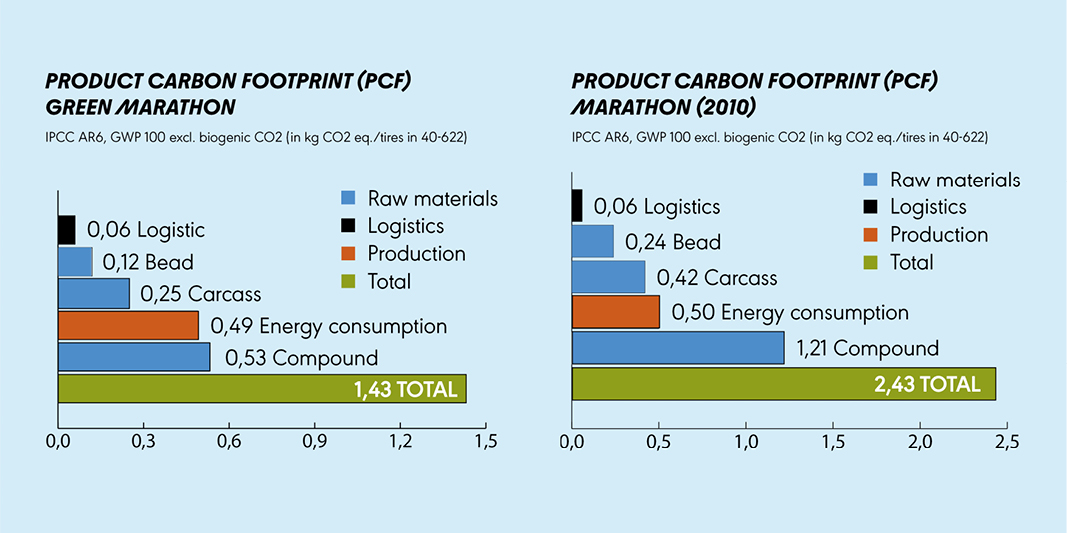

IIt is the world‘s first bicycle tire with a closed material loop - Schwalbe has now presented a detailed Life Cycle Assessment (LCA) to quantify the environmental impact of the Green Marathon. The result: With 1.43 kg CO2 equivalents (CO2eq)*, the Green Marathon saves a total of 41% CO2eq compared to its predecessor model. The Marathon from 2010 already had a lower CO2eq footprint than other bicycle tires thanks to the use of recycled materials, including in the puncture protection.

The life cycle assessment was calculated on the basis of

strict scientific criteria and in compliance with current standards.

Schwalbe worked closely with both suppliers and

pre-suppliers to collect the relevant data.

Raw materials cause the majority of emissions

The product carbon footprint (PCF) calculated with the life

cycle assessment provides a key finding: the majority of

emissions, 62% in total, are caused by raw materials. Approximately

one-third is attributed to the energy consumption

during production, while just under 3.5% is induced

by transportation logistics. This cements the importance of

Savings of 41% CO2eq compared to predecessor model thanks to recycled and renewable materials

Press Release 22.01.2024

research into raw materials and materials for reducing

environmental impacts. Schwalbe has been working

intensively on the ecological material optimization of

all tires and inner tubes since 2013.

Sebastian Bogdahn, (Environmental R&D Manager):

„The Green Marathon is the result of years of research

and development work and a flagship product - this is

underlined by the result of the life cycle assessment. At

the same time, the work doesn‘t stop there for us. Our

goal is to create life cycle assessments for all tires and

tubes by 2025 and at the same time further reduce the

environmental impact of our products.“

Schwalbe has achieved most of the CO2eq savings in

the Green Marathon by using recycled and renewable

raw materials. The tire is the first product to use 100%

recycled carbon black (rCB). The rCB of recycling

partner Pyrum Innovations AG is a direct product of

Schwalbe tire recycling and replaces fossil-based carbon

black.

What's next?

The life cycle assessment for the Green Marathon

reflects Schwalbe‘s current status of sustainable

product development and research.The familyowned

company is currently working at full speed

to further develop its life cycle assessment methodology

in order to calculate and publish life cycle

assessments for all Schwalbe core products by

2025. In addition to raw materials and production,

the use phase and disposal or recycling of the products

will also be included.

Detailed information on the calculation

To determine the CO2eq savings, a detailed PCF

of both Marathon models was calculated according

to DIN EN ISO 14067 and evaluated using

the „LCA for Experts“ software in accordance with

the current IPCC AR6 standard (GWP 100, excl.

biogenic CO2). Specifically, the study is a „partial

PCF“, which describes the total amount of greenhouse

gases emitted by a tire from raw material

extraction to the finished product („cradle-to-gate“)

and is expressed as CO2 equivalents. This

includes all raw materials that make up at least

5 percent by mass of the total weight of the tire.

By 2025, the system boundary of the life cycle assessment

is to be extended so that the complete

product life cycle from raw material extraction to

recycling („cradle-to-cradle“) is mapped and all

raw materials from 1 mass percent are included.

* The calculation is based on the best-selling tire size (40-622 with a weight of 810 grams for both models), the exact value varies for other tire sizes.

Further information:

SCHWALBE | Ralf Bohle GmbH

Press Office

Otto-Hahn-Straße 1

51580 Reichshof-Wehnrath

Phone: +49 22 65 109-0

press@schwalbe.com

www.schwalbe.com